WirelessHART Overview

WirelessHART™ is a protocol developed to form self-optimizing, self-healing, time synchronized mesh networks. It easily extends wireless capabilities from HART® technology allowing compatibility with existing HART devices, commands, and tools. It’s based on the IEEE 802.15.4™ standard and operates in the 2.4 GHz ISM band allowing for near global operation. HART version 7, maintained by the FieldComm Group, was referenced by the International Electrotechnical Commission (IEC) for development of the IEC/PAS 62591 Ed. 2.0b standard, published in 2016. The WirelessHART communication protocol is designed to meet the requirements for industrial applications, including:

- Reliability

- Plant availability

- Security

- Low maintenance

- Cost effectiveness

Reliability is achieved by using TDMA and scheduled timeslots with device communication orchestrated by a network manager. Each device within the mesh can serve as a router allowing it to relay messages from other devices within the mesh without needing to communicate directly to a gateway. Messages are forwarded to next hop devices gravitating closer toward the gateway with each hop. Packet-by-packet routing decisions are calculated, factoring spatial, temporal, and spectral diversity. This allows messages to take alternate paths across the mesh and maintain availability. Additionally, the mesh network is able to extend its range of communication and lessen the impact from radio disturbances frequently found in the challenging RF environments of process facilities.

WirelessHART has been vetted during security audits and was designed by industry experts to be intrinsically secure. It implements strong encryption using AES 128-bit keys based on the FIPS-197 standard. Using a strategy of multiple keys, comprised of common network keys, individual session keys, and integrity keys, it allows for protection against non-repudiation, “man in the middle”, “sink hole”, and other attacks. Using a separate join key allows devices to securely connect to the mesh network while preventing unauthorized devices from joining.

Mandated to maintain backwards compatibility with prior generations of HART devices, WirelessHART easily integrates into existing process plants’ installations allowing cost effective access to a wealth of new maintenance and diagnostic information. This highly valuable information allows engineers, plant operators and business analysts better management of the plant lifecycle from design, installation, configuration, operation, and maintenance.

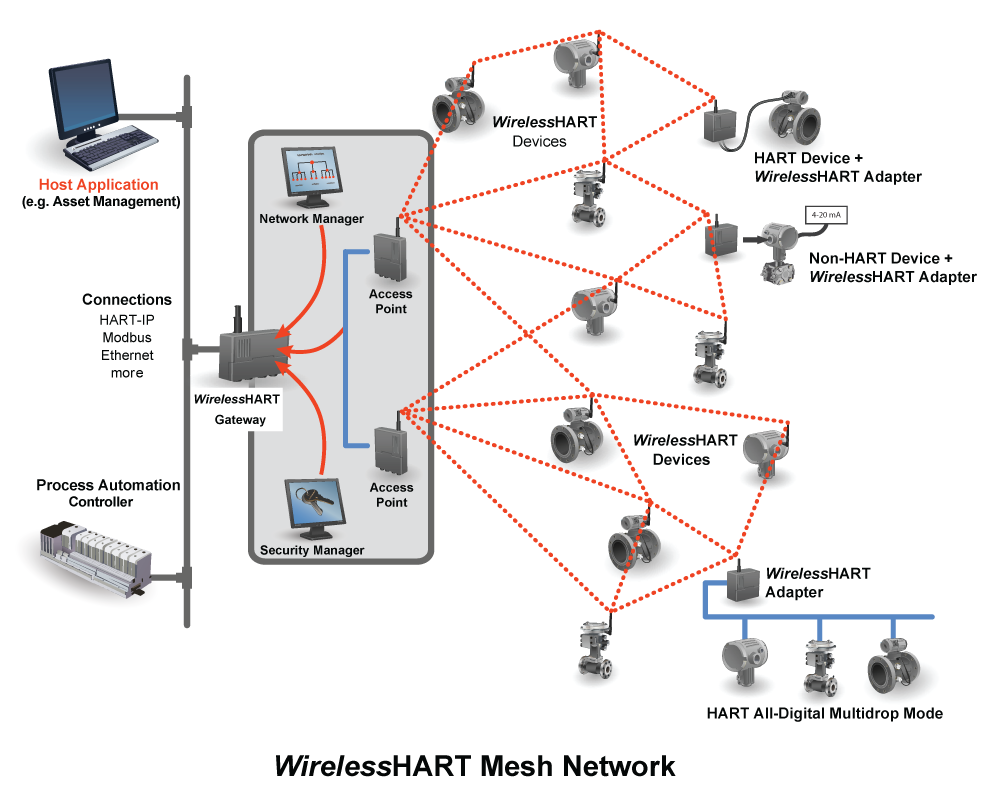

A WirelessHART network includes three main components:

Wireless field devices – nodes connecting equipment in the plant to perform sensing, monitoring, or to simply act as repeater or range extender.

Gateways – act as a centralized bridge between the WirelessHART mesh network and the plant communications network.

Network Manager – handles communication scheduling between the wireless field devices and gateways. It’s a software application that can be integrated within the gateway, host application, or process automation controller.

WirelessHART sensors create a self-forming mesh network in the process plant allowing access to data which could include:

- Temperature

- Pressure

- Level

- pH

- Flow

- Acoustics

- Vibration

- Position monitoring

- Flame & Gas

- Corrosion & Erosion

- Maintenance & Diagnostics

The list of vendors and manufacturers integrating the WirelessHART standard within their products continues to grow. Below is just a short list of some of those companies:

- ABB

- Analog Devices

- Cisco Systems

- Emerson Process Management

- Endress+Hauser

- Freescale Semiconductor (merged with NXP)

- Pepperl+Fuchs

- Siemens

Additional WirelessHART resources:

IEC 62591 Ed 2.0 b:2016 Standard

WirelessHART Protocol Specifications for HART Communication Protocol

WirelessHART: Real-Time Mesh Network for Industrial Automation (Book on Amazon)

Slàinte!