Cisco expands LoRaWAN Portfolio

With the Cisco Mining Summit 2023 and CiscoLive Amsterdam 2023 recently wrapping up, there have been some exciting announcements from Cisco in the Industrial IoT space. This blog focuses on the new LoRaWAN tech from Cisco.

What is LoRaWAN?

LoRaWAN is a wireless protocol for IoT and Industrial IoT (IIoT) devices. If you weren’t aware, Cisco has been in the LoRaWAN game since the inception and is a founding member of the LoRaWAN alliance (2015) – the body responsible for LoRaWAN standards which also certifies device interoperability.

LoRaWAN provides the following benefits:

Unlicensed spectrum

- License free global ISM band, sub 1GHz (868/915MHz in EU/NA)

- Highly scalable deployments with low-cost private/public/hybrid models

Long Distance Coverage

- Connect thousands of endpoints to a single gateway

- Easily reach up to 15Km radius in rural areas

Low Data Rates

- Very low data rates (300bps to 21kps)

- Adaptive rates based on signal distance and quality

Low Power Consumption

- Battery powered endpoints (think coin cell batteries & energy harvesting)

- Upwards of 10-year lifetimes (depending on the device class)

Why use LoRaWAN in Mining (or several other) applications?

Machine Vibration Monitoring

- Collect data for predictive modelling and maintenance (premature failure, excessive vibration, operation outside normal parameters)

- Monitor legacy conveyor systems without built-in monitoring

Physical Security / Maintenance

- Monitor remote/isolated buildings

- Alert on remote entry — door open/close or prolonged state

- Monitor leaks or spills

- Theft prevention

- Restroom facilities

- Geofencing

Communications (Comms) Trailer Monitoring

- Track GPS location in the mine

- Alert on power loss (dying gasp)

- Send remote restart to power-cycle devices

- Door/cabinet open

Air Quality Monitoring

- Regulatory compliance

- Rogue particulates (CO2, SO2, etc…)

Cable Management

- Trailing cable location

- Shock

- Energy status (electric current)

LoRaWAN Gateway Devices

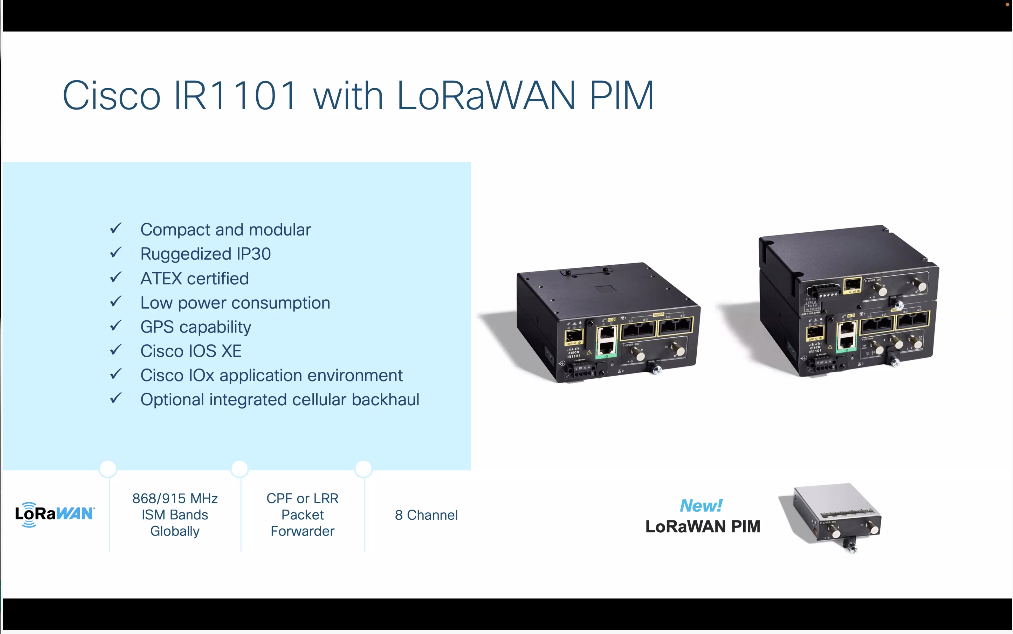

Cisco already has a rugged outdoor LoRaWAN gateway with the IXM LoRaWAN Gateway. A new LoRaWAN PIM module was announced for the IR1101 Industrial Router allowing LoRaWAN communication to remote end devices coupled with the LTE backhaul capabilities of the IR1101. What does this mean? This opens the door for cost-reduced monitoring of remote and isolated assets with a single LTE subscription, as opposed to one per sensor. The IR1101 is an industrial class router with DIN rail mounting, but it is intended to be mounted within the environmental protection of an indoor installation.

A spec overview of the IR1101 LoRaWAN module is shown below in a slide from the Cisco Mining Summit presented by Kevin Holcomb.

New LoRaWAN Sensor and Bridge Announced

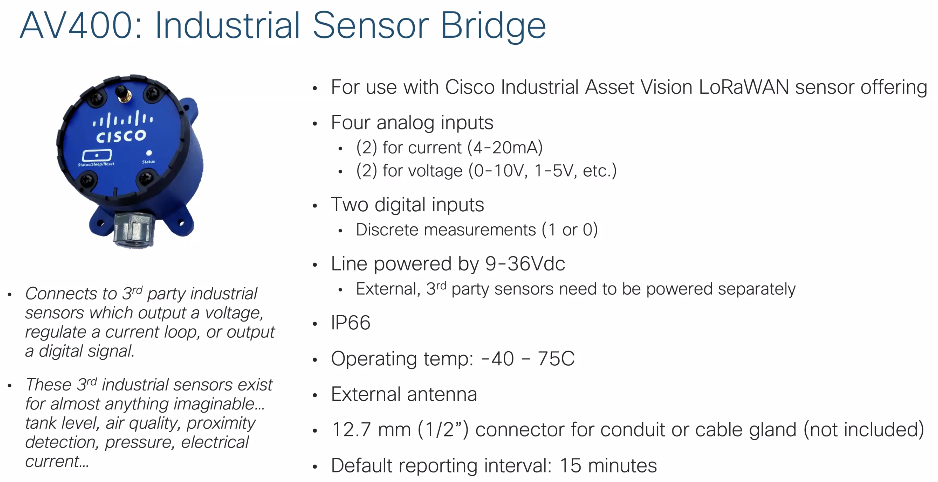

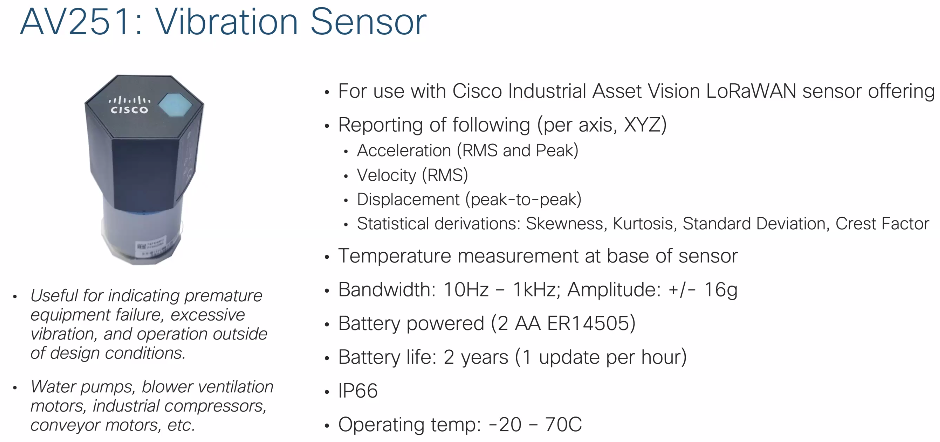

Cisco also announced two new LoRaWAN end devices (sensors) – the AV400: Industrial Sensor Bridge and the AV251: Vibration Sensor. This complements the 10 sensors already available. As usual, these sensors can be easily integrated into the Cisco Industrial Asset Vision Solution by quickly scanning a QR code for simple on-boarding. Users are insulated from any complexities of configuring a network server.

The AV400 Bridge is a brilliant addition to the portfolio and allows integration with many existing sensors most likely deployed in your environment as well. The bridge simply allows remote wireless access to these existing sensors over LoRaWAN.

The AV251: Vibration sensor is also a welcome addition. Excessive vibrations may influence the durability and reliability of machinery systems or structures causing problems such as damage, unplanned stoppages, or disaster. Analysis of vibration measurement is an important countermeasure to prevent many of these problems. Collecting and forwarding vibration sensor data to analytics engines allows plant operators to take maintenance action at the right time to minimize unplanned outages and reduce unnecessary maintenance. Vibration data can also be forwarded to business intelligence teams as input into predictive modelling algorithms.

With the announcement of the recent sensors, Cisco brings their total up to LoRaWAN 12 sensors (10 existing + 2 added above). A summary of the available sensors is listed in the table below:

| Sensor Features | Cisco Part Name |

|---|---|

| Outdoor Temperature & Humidity | AV200 |

| Indoor Temperature & Humidity | AV201 |

| Product Temperature Sensor | AV202 |

| Refrigerator Temperature & Humidity Sensor | AV203 |

| Door & Window Sensor | AV204 |

| Water Leak Sensor | AV205 |

| Light Level Sensor | AV206 |

| Indoor Occupancy Sensor | AV207 |

| Machine Temperature Sensor | AV250 |

| Outdoor GPS Sensor | AV300 |

| Industrial Sensor Bridge | AV400 |

| Vibration Sensor | AV251 |

LoRaWAN Servers

As part of an effort to simplify the device on-boarding experience and complexities of traditional IT with its countless CLI commands, Cisco has rolled out Cisco Industrial Asset Vision (IAV) Solution.

Cisco Industrial Asset Vision (IAV) is an “out-of-the-box” LoRaWAN solution developed by Cisco. It allows users to roll-out a LoRaWAN solution without needing to know all the details behind how LoRaWAN works. All the complexities of the LoRaWAN architecture boil down to three components: sensors, Cisco LoRaWAN gateway, and IAV dashboard/mobile app as seen below:

Now this is where things get a little interesting:

Cisco LoRaWAN sensors and gateways ONLY work with Cisco network servers. Gateways and sensors are brought online after scanning a QR code which loads serial numbers into a dashboard. When Gateways are hard coded to connect to a join server, called the Cisco PNP Connect, Cisco PNP redirects the gateway to the appropriate IoT Operations Dashboard. The dashboard is responsible for sending the initial configuration to devices. Devices are authenticated with more than just the serial number; a SUDI certificate is integrated in the Cisco ACT2 chip that comes with all devices.

Once a device and the cloud network are mutually authenticated, a secure management tunnel is established using FlexVPN. All communication is then sent through this tunnel for the duration of the session. Having gateways configured to always call home removes the burden on administrators from managing a list of regularly changing IP addresses from WAN failovers or 3rd party operator changes.

Depending on the network operator, IoT administrators may not have direct IP connectivity to their gateways. Solving this problem, the IoT Dashboard provides a path between gateways and the Dashboard which is only accessible from within the Dashboard.

Cisco IoT Dashboard

The Cisco IoT Dashboard is an umbrella term for a portfolio of software products. Currently, the IoT Operations Dashboard (OD) supports the following services:

- Edge Device Manager – to configure, deploy, and monitor supported industrial network devices

- Secure Equipment Access – to connect assets deployed in remote locations

- Edge Intelligence – to enable edge to multi-cloud data orchestration

- Asset Vision – to monitor assets and facilities using Cisco industrial sensors

Geofencing and threshold alerts can be configured to generate notifications through IoT Operations Dashboard with the goal being to provide the ultimate single pane of glass for managing and operating your Cisco IoT devices.

My Thoughts

LoRaWAN is a purpose-built technology that fills a definite hole in the wireless marketplace. Its rapid adoption has spurred an industry to generate thousands of sensors and actuators. It is worth noting that Cisco does not yet have a LoRaWAN actuator – but I am sure one will be released shortly. Security is top of mind within this IoT portfolio where often the weakest link is distributing keys between devices and platforms.

As LoRaWAN has quickly evolved, so have its standards – forking into several different versions resulting in a mix of terminology for items like Join Keys, AppEUI, DevEUI, and DeviceIDs. Initial system configuration or adding sensors can be a little confusing to new administrators. Cisco waves a magic wand over this problem with simple QR code scanning and certificate distribution — ultimately resulting is the establishment of secure communication channels so that users do not need to worry about the magic behind the scenes.

The user experience is great, but it comes with a risk of strong vendor lock in. Most LoRaWAN solutions are highly portable and could be migrated from public to private to hybrid architectures, but doing so within the Cisco solution would break the simplicity of the secure underpinnings. If Cisco produces the sensors you are looking for, perhaps the compromise is worth it. If you’re still eyeing up end devices from other manufacturers, maybe you’ll need to take on the burden of securing your LoRaWAN infrastructure and exporting the data in useful user applications for visualization and alerting.

The great thing is that we have choice and the answer should always be the solution that best meets your design goals.

Slàinte!

Resources

Cisco Wireless Gateway for LoRaWAN Data Sheet

https://www.cisco.com/c/en/us/products/collateral/se/internet-of-things/datasheet-c78-737307.html

IoT Operations Dashboard

https://developer.cisco.com/docs/iotod/

Mining Summit – LoRaWAN – low bir rate, large geography, high volume of sensors